In a significant advancement for the bedding manufacturing industry, the introduction of state-of-the-art mattress rolling and pressing machines is set to streamline production processes, enhance efficiency, and reduce environmental impact. These technological innovations promise to transform the way mattresses are manufactured, packed, and distributed, offering numerous benefits to both manufacturers and consumers.

Mattress Rolling Machine: Compact and Convenient

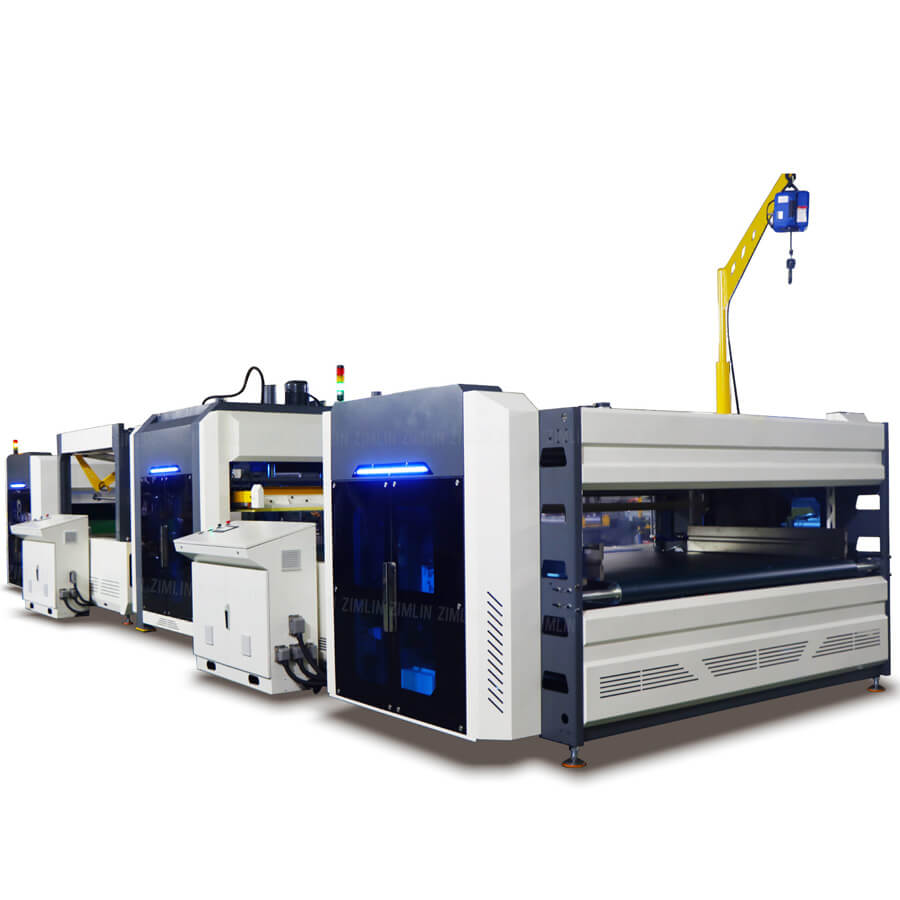

The mattress rolling machine has emerged as a game-changer in the bedding industry. This machine efficiently rolls mattresses into a compact form, making them easier to store and transport. By reducing the volume of mattresses, manufacturers can optimize their storage space and significantly cut down on shipping costs.

The rolling process involves compressing the mattress and then rolling it tightly without causing any damage to the internal structure. This method ensures that the mattress retains its original shape and quality once unpacked by the consumer. The compact packaging also makes it more convenient for consumers to handle and move the mattress into their homes, especially through tight spaces like staircases and narrow doorways.

Mattress Pressing Machine: Precision and Durability

Alongside the rolling machine, the mattress pressing machine offers a complementary solution by ensuring precise and uniform compression of mattresses. This machine is designed to press mattresses to a specific thickness, allowing for consistent quality and firmness across all products. The pressing process not only enhances the durability of the mattress but also prepares it for the rolling stage, ensuring a seamless transition between the two processes.

The mattress pressing machine employs advanced technology to apply even pressure across the entire surface of the mattress. This uniform compression is critical for maintaining the structural integrity and comfort of the mattress, ensuring that every product meets the highest standards of quality.

Environmental and Economic Benefits

The adoption of these machines offers significant environmental advantages. By reducing the size of the mattresses, the rolling and pressing processes minimize the need for bulky packaging materials, thereby reducing waste. Additionally, the compact size allows for more efficient transportation, leading to lower carbon emissions and a reduced environmental footprint.

Economically, the machines offer substantial cost savings for manufacturers. The reduced volume and weight of the packaged mattresses lead to lower shipping costs, while the increased efficiency in production processes results in higher output and lower labor costs. These savings can potentially be passed on to consumers, making high-quality mattresses more affordable and accessible.

Industry Adoption and Future Prospects

The bedding industry has shown a keen interest in adopting these innovative machines. Several leading manufacturers have already integrated them into their production lines, reporting significant improvements in efficiency and product quality. As the technology continues to evolve, further enhancements in the design and functionality of mattress rolling and pressing machines are anticipated, promising even greater benefits for the industry.

In conclusion, the introduction of mattress rolling and pressing machines marks a significant milestone in the bedding manufacturing industry. These innovations not only improve operational efficiency and product quality but also contribute to environmental sustainability and cost savings. As more manufacturers embrace these technologies, the future of mattress production looks promising, with enhanced benefits for both producers and consumers.