Introduction to Steel Detailing

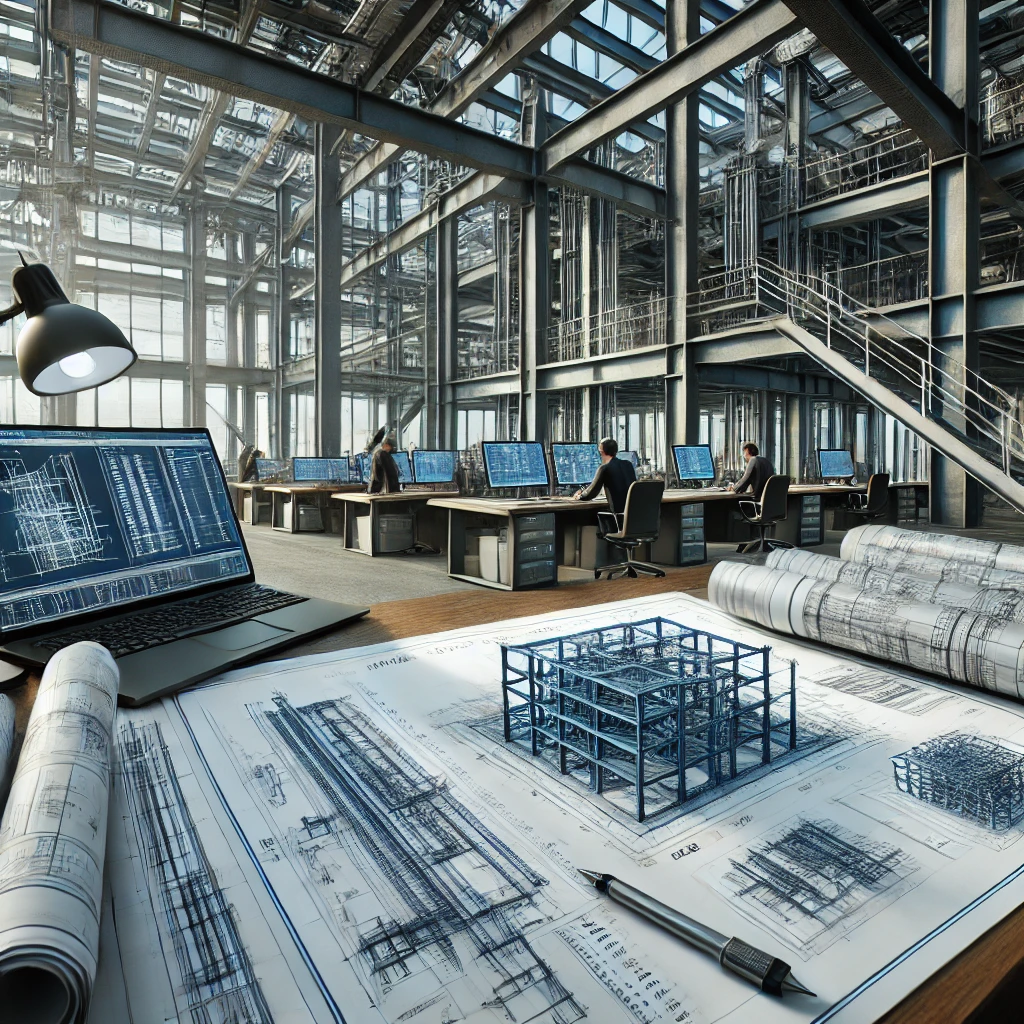

Steel Detailing Services is a critical process in the construction and engineering industry. It involves the creation of detailed drawings and plans that guide the fabrication and erection of steel components used in buildings, bridges, industrial structures, and other infrastructure projects. These precise plans are vital for ensuring structural integrity and project efficiency.

In modern construction, steel detailing acts as the backbone of effective project execution. Without accurate detailing, even the most sophisticated architectural design can face costly delays and structural issues. This service ensures seamless coordination between architects, engineers, fabricators, and contractors.

Key Components of Steel Detailing

Steel detailing is broadly divided into two categories:

1. Structural Steel Detailing: This focuses on creating detailed plans for beams, columns, braces, and other load-bearing steel elements. These drawings are essential for steel fabricators to cut and weld pieces accurately.

2. Rebar Detailing: This involves designing and documenting the placement of steel reinforcement bars in concrete structures. These details are crucial for ensuring strength and durability in concrete construction.

Another major element of steel detailing is the creation of two primary types of drawings:

- Shop Drawings: These are highly detailed representations that fabricators use to manufacture each steel component.

- Erection Drawings: These outline the precise location and installation method for each piece of steel at the construction site.

The Steel Detailing Process Explained

The steel detailing process is complex and meticulous. It usually begins after receiving the structural and architectural design plans. Here’s how it typically unfolds:

1. Initial Design Coordination: The detailer collaborates with architects and structural engineers to interpret design intent and project specifications.

2. Modeling and Drafting: Using advanced software like Tekla Structures, SDS/2, or AutoCAD, the detailer creates 3D models and 2D drawings. These tools ensure accuracy and help in identifying potential conflicts early in the process.

3. Quality Control and Error Checking: Before submission, every drawing undergoes a rigorous quality assurance check to ensure it complies with industry standards like AISC (American Institute of Steel Construction) or local codes. Peer reviews and software-based clash detection are often used to eliminate errors.

This process streamlines communication across the entire project lifecycle and significantly reduces costly rework on-site.

Who Needs Steel Detailing Services?

Steel detailing is essential for a variety of stakeholders in the construction ecosystem:

Architects and Engineers: They rely on accurate detailing to bring their designs to life while maintaining safety and structural feasibility.

Fabricators and Manufacturers: Precise shop drawings allow fabricators to cut, drill, and assemble steel components with little room for error.

Contractors and Builders: Erection drawings provide the necessary guidance to assemble the structure correctly and efficiently on-site.

Whether it’s a residential high-rise, a commercial complex, or an industrial plant, steel detailing services are integral to achieving quality outcomes.

Advantages of Professional Steel Detailing

Hiring professional steel detailers provides multiple advantages that enhance both efficiency and reliability:

- Improved Accuracy: Highly detailed drawings minimize errors and rework, which can save thousands of dollars in project costs.

- Faster Timelines: Precise coordination among teams speeds up the entire construction process, from fabrication to on-site erection.

- Cost Efficiency: Accurate material take-offs help reduce waste, avoid over-ordering, and keep the project within budget.

- Enhanced Collaboration: Professional detailing fosters better communication between all project stakeholders, leading to smoother execution.

These benefits make steel detailing not just a technical necessity but a strategic advantage in construction projects.

BIM Integration in Steel Detailing

Building Information Modeling (BIM) is revolutionizing the steel detailing industry. By incorporating 3D modeling and real-time data exchange, BIM enhances every stage of the detailing process.

- Clash Detection: BIM tools can identify conflicts between steel elements and other building systems (like plumbing or electrical) before they become on-site issues.

- Collaboration: Cloud-based BIM platforms allow architects, engineers, and detailers to work in tandem, updating models in real-time.

- Visualization: 3D renderings help stakeholders better understand the structure, facilitating approvals and early-stage planning.

Incorporating BIM into steel detailing results in fewer errors, improved planning, and higher client satisfaction.

Common Challenges in Steel Detailing

Despite technological advancements, steel detailing still comes with its share of challenges:

- Design Discrepancies: Misalignments between architectural and structural plans can lead to detailing errors.

- Frequent Revisions: Late-stage design changes often require quick turnaround times for updating shop and erection drawings.

- Communication Gaps: Poor collaboration between project stakeholders can delay approvals and create on-site confusion.

Addressing these challenges requires skilled detailers, standardized workflows, and robust communication tools.

Industry Standards and Compliance

Steel detailing must adhere to rigorous industry standards to ensure safety, reliability, and legal compliance:

- AISC (American Institute of Steel Construction): Offers guidelines on fabrication, erection, and design.

- NISD (National Institute of Steel Detailing): Provides certification and promotes professionalism among detailers.

- Local Building Codes: Must be considered to meet regional safety and construction requirements.

Following these standards helps avoid legal liabilities and ensures that structures can withstand environmental and operational stresses.

Choosing the Right Steel Detailing Partner

Selecting the right partner is critical to project success. Here are key factors to consider:

- Experience and Expertise: Look for detailers with a strong portfolio and knowledge of local codes and international standards.

- Software Proficiency: Ensure the firm uses industry-standard software like Tekla, Revit, or SDS/2.

- Quality Assurance Processes: Ask about internal checks, peer reviews, and revision tracking systems.

- Client Communication: Transparent and regular updates are essential for a smooth working relationship.

Choosing a reliable partner reduces risk, improves outcomes, and leads to long-term project success.

Outsourcing Steel Detailing Services

Many companies choose to outsource steel detailing services for increased efficiency and cost-effectiveness. Here’s why outsourcing can be advantageous:

- Access to Expertise: Outsourced firms often specialize in steel detailing and maintain skilled teams with deep experience.

- Scalability: Easily scale up or down based on project demands without the need for long-term staffing commitments.

- Cost Savings: Reduce overhead costs related to hiring, training, and software licensing.

- Time Zone Advantage: Offshore teams can continue work during your off-hours, speeding up project turnaround times.

When selecting an outsourcing partner, ensure they align with your quality standards, communication expectations, and project timelines.

Case Studies and Real-World Examples

Case Study 1: Commercial High-Rise Project A detailing firm provided comprehensive shop and erection drawings for a 30-story building, enabling fabricators to meet tight deadlines. The precision of detailing helped reduce material waste by 12% and eliminated 95% of on-site design changes.

Case Study 2: Industrial Manufacturing Facility A global engineering company partnered with an outsourced detailing firm to manage an industrial plant expansion. The use of BIM and real-time cloud collaboration shortened the project duration by four weeks and improved stakeholder coordination.

These examples highlight how professional detailing can directly impact time, cost, and construction quality.

The Future of Steel Detailing

Steel detailing is rapidly evolving, thanks to advancements in technology and changing construction demands. Here’s what lies ahead:

- AI Integration: Artificial Intelligence is being used for auto-checking models, suggesting corrections, and optimizing material usage.

- Cloud-Based Collaboration: More firms are adopting real-time cloud platforms for seamless global teamwork.

- Sustainability Focus: Steel detailing is now considering environmental impact, optimizing designs for minimal material waste and energy efficiency.

As technology continues to progress, the detailing industry will play an even more vital role in smarter, faster, and greener construction.

SEO-Optimized Strategies for Steel Detailing Companies

To stand out in a competitive market, steel detailing companies must invest in strong SEO practices:

- Local SEO Optimization: Ensure your business is listed on Google Business Profile, directories, and maps for location-based searches.

- Targeted Keywords: Use keywords like “steel detailing services,” “shop drawings,” and “BIM coordination” strategically in your content.

- Content Marketing: Regularly publish blog posts, case studies, and whitepapers to build authority and attract backlinks.

- YouTube Integration: Create and optimize videos showing your process, software tips, or project walk-throughs. Embed these in your website for greater engagement.

- Mobile Optimization: Ensure your website is fast-loading and mobile-friendly to rank well on Google.

These strategies can drive traffic, generate leads, and establish your brand as a leader in the industry.

Conclusion

Steel detailing is a cornerstone of modern construction, ensuring that complex structures are safe, precise, and economically built. From initial design interpretation to fabrication and final assembly, steel detailers play a pivotal role in project success.

By embracing technological innovations, adhering to strict industry standards, and leveraging SEO best practices, both detailers and clients can achieve outstanding results in today’s fast-paced construction landscape.

FAQs

1. What’s the difference between shop drawings and erection drawings? Shop drawings are detailed plans for fabrication, while erection drawings show how each component is assembled on-site.

2. How long does the steel detailing process take? Timeframes vary depending on project complexity, but it can range from a few days to several weeks.

3. What are the risks of skipping proper detailing? Skipping proper detailing can lead to costly errors, delays, structural failures, and safety hazards.

4. What industries benefit most from steel detailing? Industries such as commercial construction, industrial manufacturing, and infrastructure development rely heavily on steel detailing.

5. How does steel detailing support sustainable construction? It minimizes material waste, optimizes fabrication, and integrates with green building technologies through BIM and other smart solutions.

Learn about Streamlining Your Construction Budget with Expert Lumber Takeoff Solutions