Introduction

When it comes to controlling the flow of fluids in pipelines, butterfly valves are one of the most efficient and widely used solutions. These valves offer a compact, lightweight design with quick and easy operation, making them suitable for various industries, including water treatment, oil & gas, pharmaceuticals, and food processing.

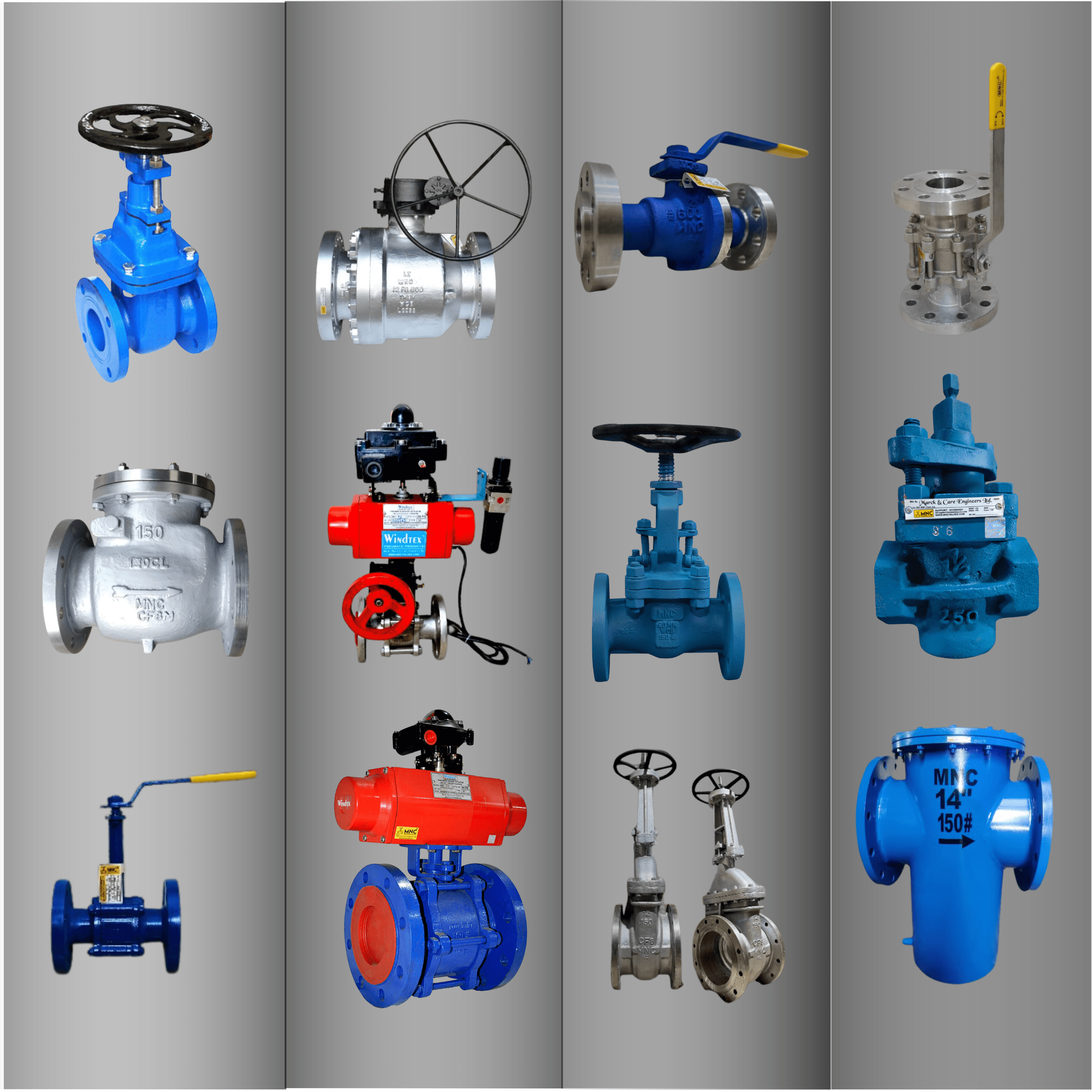

As a trusted butterfly valve manufacturer in Ahmedabad, Marck & Care Engineers Ltd specializes in designing high-quality butterfly valves that meet global industry standards. In this blog, we will explore the working principle of butterfly valves, their key components, types, advantages, and applications.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn rotational valve used to start, stop, or regulate fluid flow. It gets its name from the disc inside the valve, which resembles a butterfly when rotated. When the disc is turned parallel to the flow, the valve is fully open, allowing unrestricted movement of fluids. When turned perpendicular, it blocks the flow, closing the pipeline.

These valves are widely used due to their cost-effectiveness, energy efficiency, and durability. Compared to other valve types like gate or ball valves, butterfly valves offer a lower pressure drop and require minimal space for installation.

Key Components of a Butterfly Valve

A butterfly valve consists of several essential components that ensure its efficient functioning:

- Body – The outer casing that houses all internal components and provides structural integrity.

- Disc – The rotating component responsible for regulating fluid flow.

- Stem (Shaft) – The rod that connects the disc to the actuator or handle, enabling movement.

- Seat – The sealing component that prevents leaks when the valve is in the closed position.

- Actuator or Handle – The mechanism used to operate the valve, which can be manual, pneumatic, hydraulic, or electric.

Each of these components plays a crucial role in ensuring smooth and efficient fluid control in industrial applications.

Working Principle of Butterfly Valves

The working mechanism of a butterfly valve is simple yet highly effective. It operates on a quarter-turn rotational movement:

- Closed Position: When the disc is perpendicular to the flow direction, it completely blocks the passage, stopping the fluid.

- Open Position: A 90-degree turn of the actuator moves the disc parallel to the flow, allowing the liquid or gas to pass freely.

- Partially Open Position: The valve can also be adjusted to a partially open position, regulating the flow as required.

Butterfly valves can be operated manually using a lever or automatically with actuators, which can be pneumatic, hydraulic, or electric. Automated valves are commonly used in large industrial plants where remote control is required.

Types of Butterfly Valves

Butterfly valves come in different types, depending on their design, sealing method, and application. The most common types include:

1. Concentric Butterfly Valve

- The disc is positioned in the center, and the stem passes through the middle.

- Used for low to medium-pressure applications.

- Commonly found in water distribution and HVAC systems.

2. Double Offset Butterfly Valve

- The stem is slightly offset from the center, reducing wear and tear.

- Provides a better seal and is used in high-pressure applications.

- Suitable for oil refineries, chemical plants, and steam systems.

3. Triple Offset Butterfly Valve

- The disc and seat have a metal-to-metal contact, making it highly durable.

- Designed for extreme conditions, such as high temperatures and high-pressure environments.

- Used in power plants, shipbuilding, and the petrochemical industry.

Each type of butterfly valve is designed to cater to specific operational needs, ensuring maximum efficiency and reliability.

Advantages of Butterfly Valves

Butterfly valves are widely preferred over other valve types due to their numerous benefits, including:

- Compact & Lightweight: Requires less space and is easier to install.

- Cost-Effective: More affordable than gate or ball valves.

- Quick Operation: A simple 90-degree turn opens or closes the valve instantly.

- Low Maintenance: Minimal moving parts reduce wear and tear.

- Energy-Efficient: Causes minimal pressure drop, ensuring smooth fluid flow.

- High Durability: Available in different materials for corrosion and temperature resistance.

These advantages make butterfly valves the ideal choice for industries where fluid flow regulation is critical.

Applications of Butterfly Valves

Butterfly valves are used in a wide range of industries, including:

- Water Supply & Wastewater Treatment: Managing water flow in treatment plants and municipal supply lines.

- Oil & Gas Industry: Controlling the flow of crude oil, natural gas, and refined products.

- Food & Beverage Industry: Maintaining hygienic and precise control over liquid products.

- Pharmaceutical Industry: Ensuring precise dosing and fluid movement in medicine production.

- Chemical & Petrochemical Industry: Handling corrosive and high-pressure chemicals safely.

- HVAC Systems: Regulating air and water flow in heating and cooling systems.

Due to their versatility, butterfly valves play a critical role in ensuring efficiency, safety, and cost-effectiveness across different sectors.

Why Choose Marck & Care Engineers Ltd?

When selecting a butterfly valve manufacturer in Ahmedabad, choosing a reliable and experienced supplier is crucial. Marck & Care Engineers Ltd is a trusted name in the industry, known for producing high-quality, durable, and efficient butterfly valves.

What Sets Us Apart?

✔ ISO-Certified Manufacturing – Ensuring top-notch quality and safety standards. ✔ Advanced Engineering – Using cutting-edge technology for precision manufacturing. ✔ Wide Range of Valves – From concentric to triple offset butterfly valves. ✔ Customization Options – Tailored solutions for specific industrial applications. ✔ Global Clientele – Trusted by industries across India and beyond.

At Marck & Care Engineers Ltd, we focus on delivering superior valve solutions that enhance operational efficiency and safety.

Conclusion

Butterfly valves are essential components in various industries due to their compact design, efficiency, and cost-effectiveness. Their simple working principle and versatile applications make them a preferred choice for fluid control.

As a leading butterfly valve manufacturer in Ahmedabad, Marck & Care Engineers Ltd provides high-performance butterfly valves designed for long-lasting durability and optimal flow regulation. If you’re looking for reliable butterfly valves for your industrial needs, get in touch with us today!