When sourcing equipment for the dairy industry, choosing the right partner is critical for ensuring hygiene, efficiency, and regulatory compliance. If you’re in the market for reliable dairy valve manufacturers in Ahmedabad, the process can seem overwhelming due to the number of suppliers available. However, selecting the right manufacturer isn’t just about cost—it’s about long-term value, safety, and performance.

Understand Your Requirements

Before approaching any manufacturer, it’s essential to define your specific requirements. Dairy applications require valves that meet stringent hygiene standards, such as those defined by 3-A Sanitary Standards or EHEDG. Consider factors like:

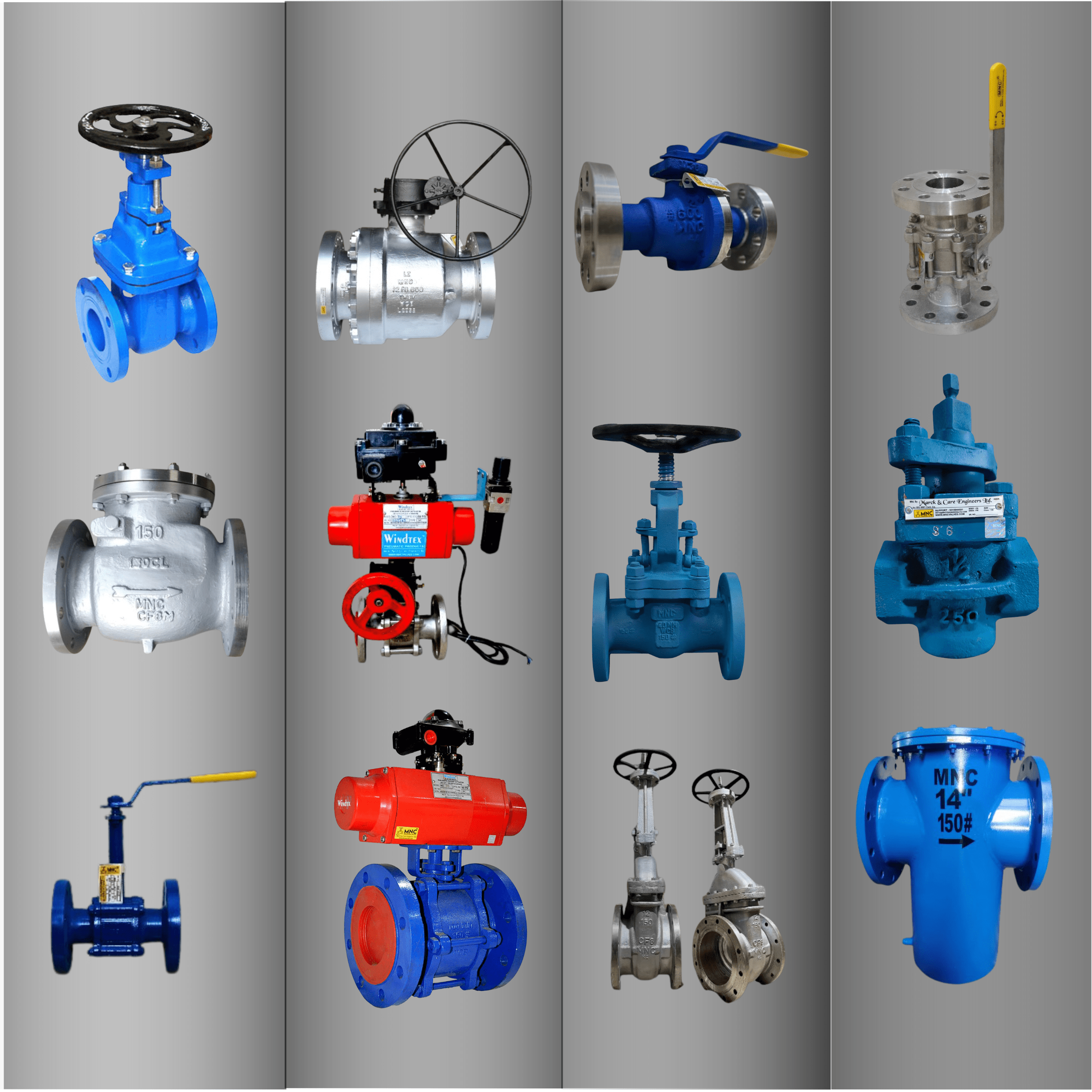

- Type of dairy valves needed: Butterfly valves, ball valves, diaphragm valves, or NRV (non-return) valves.

- Material compatibility: Stainless steel (especially SS 304 or SS 316) is standard due to its corrosion resistance and ease of cleaning.

- Operating conditions: Pressure, temperature, and the type of dairy product being processed.

Knowing exactly what your production process demands will help you filter through potential manufacturers more effectively.

Look for Compliance and Certifications

In a sensitive industry like dairy processing, compliance is non-negotiable. The right manufacturer will offer valves that meet national and international standards for food safety and quality. Make sure the company provides:

- ISO certifications

- 3-A Sanitary Standards compliance

- Food-grade material documentation

- Third-party testing results, if available

These certifications aren’t just pieces of paper—they are assurances that the valves will perform safely and efficiently over time.

Evaluate Manufacturing Capabilities

The quality of a valve is directly influenced by the manufacturing process. Opt for manufacturers with in-house production facilities that use modern machinery and stringent quality control. Visit their factory if possible or request a virtual tour. Check if they use:

- CNC machines for precision machining

- Polishing techniques for smooth finishes (critical in dairy)

- Quality control systems at every stage of production

Manufacturers with robust production capabilities are more likely to deliver consistent, high-performance products.

Assess the Technical Expertise

Working with a technically sound team is essential. A knowledgeable manufacturer can provide guidance on which valve type suits your process best, help troubleshoot operational issues, and even customize valves to fit unique applications.

When evaluating a dairy valve manufacturer in Ahmedabad, ask questions like:

- Do they have experience working with other dairy processing plants?

- Can they provide case studies or testimonials?

- Do they offer post-installation support and training?

A team that understands your industry and can anticipate your needs is invaluable.

Consider After-Sales Support

Even the best equipment can run into occasional problems. A trustworthy manufacturer will not just sell the product but also stand by it. Ensure the company offers:

- Prompt technical support

- Ready stock of spare parts

- Installation and maintenance guidance

- Warranty coverage

Strong after-sales service reflects the company’s confidence in its products and its commitment to customer satisfaction.

Compare Value, Not Just Price

It’s tempting to opt for the lowest quote, but that can be a costly mistake in the long run. Cheap valves may compromise on build quality, leading to contamination risks or frequent breakdowns. Instead of focusing solely on the upfront cost, evaluate the overall value:

- Longevity of the valve

- Maintenance requirements

- Operational efficiency

- Energy consumption

A slightly higher investment in a high-quality valve from a reputable manufacturer can lead to long-term savings and peace of mind.

Why Choose Marck & Care Engineers Ltd?

At Marck & Care Engineers Ltd, we understand the critical role valves play in dairy processing. As one of the leading dairy valve manufacturers in Ahmedabad, we offer a complete range of hygienic, high-performance valves designed specifically for the dairy industry.

All our valves are manufactured in-house using premium stainless steel and undergo rigorous quality checks to meet international standards. We offer butterfly valves, NRVs, ball valves, diaphragm valves, and other custom solutions tailored to your exact needs. With over a decade of industry experience, our team offers unmatched technical support, reliable after-sales service, and a commitment to innovation and quality.

Conclusion

Choosing the right dairy valve manufacturers in Ahmedabad is a strategic decision that impacts product safety, plant efficiency, and regulatory compliance. By considering your operational needs, verifying certifications, evaluating technical expertise, and assessing after-sales support, you can make an informed choice that benefits your dairy operations for years to come. With a proven track record, advanced manufacturing, and a customer-first approach, Marck & Care Engineers Ltd is your trusted partner in hygienic valve solutions.