The marine industry relies heavily on the smooth operation of ship engines to ensure safe and efficient voyages. Given the harsh conditions at sea—including saltwater exposure, extreme temperatures, and continuous operation—engine components face significant wear and tear. Industrial oils play a crucial role in protecting these engines, enhancing performance, and extending their lifespan.

The Challenges Faced by Marine Engines

Ship engines operate under some of the most demanding conditions, including:

- Corrosion from Saltwater: Exposure to seawater accelerates rust and corrosion in engine parts.

- High Load and Pressure: Marine engines run continuously for long durations, leading to increased friction and heat.

- Contaminant Buildup: Dirt, soot, and sludge can accumulate, reducing efficiency and causing breakdowns.

- Temperature Extremes: Fluctuations between hot engine operation and cooler external temperatures can affect lubrication stability.

Without proper lubrication, these factors can lead to engine failure, costly repairs, and downtime.

How Industrial Oils Protect Marine Engines

High-quality industrial oils are specially formulated to address the unique challenges of marine applications. Here’s how they safeguard ship engines:

1. Superior Corrosion Protection

Marine-grade oils contain anti-corrosion additives that form a protective layer on engine components, preventing rust and oxidation caused by saltwater exposure.

2. Enhanced Wear Resistance

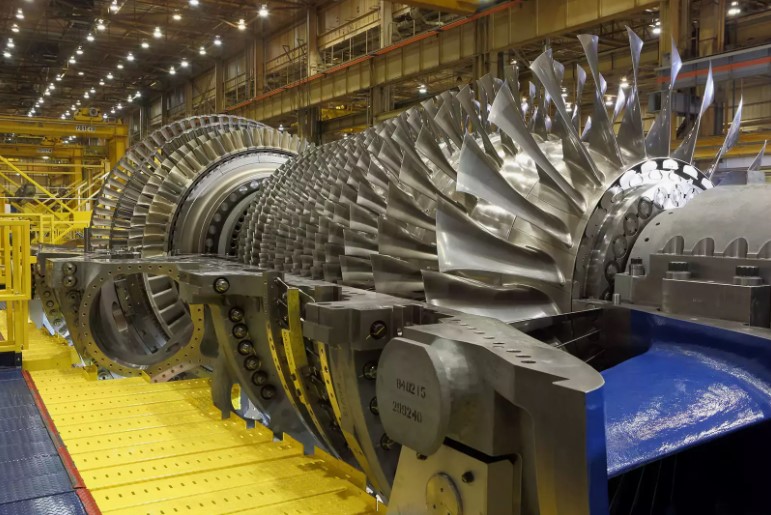

Advanced lubricants reduce metal-to-metal contact, minimizing friction and wear even under heavy loads. This extends the lifespan of critical engine parts like pistons, bearings, and crankshafts.

3. Thermal Stability

Industrial oils designed for marine use maintain viscosity in extreme temperatures, ensuring consistent lubrication whether the engine is operating in tropical heat or icy waters.

4. Detergent and Dispersant Properties

Special additives keep engines clean by preventing sludge and deposit buildup. This improves fuel efficiency and reduces the risk of clogged filters and oil passages.

5. Water Resistance

Marine lubricants are engineered to resist water contamination, preventing emulsification and maintaining lubrication effectiveness even in humid or wet conditions.

Choosing the Right Industrial Oil for Marine Engines

Not all lubricants are suitable for marine applications. When selecting industrial oils for ship engines, consider:

- Viscosity Grade: Must match the engine manufacturer’s specifications.

- API and OEM Approvals: Ensures compatibility with marine engine requirements.

- Additive Package: Look for anti-wear, anti-corrosion, and anti-oxidation properties.

- Synthetic vs. Mineral Oils: Synthetic oils often provide better performance in extreme conditions.

Conclusion

The right industrial oil is essential for maintaining the efficiency, reliability, and longevity of marine engines. By reducing wear, preventing corrosion, and ensuring smooth operation, high-performance lubricants help vessels navigate the toughest conditions with confidence.

For superior marine-grade industrial oils that deliver unmatched protection and performance, trust Rumanza Lubricants—your partner in advanced lubrication solutions.