In today’s competitive manufacturing landscape, businesses are constantly seeking ways to reduce costs while maintaining high-quality production standards. One of the most effective methods to achieve this is through efficient waterjet cutting services. This advanced technology not only offers precision and versatility but also contributes to significant cost savings. In this article, we will explore how waterjet cutting can help businesses save money, the advantages of using this method, and tips for maximizing efficiency.

Understanding Waterjet Cutting Technology

Waterjet cutting technology utilizes a high-pressure stream of water, often mixed with abrasive materials, to cut through various materials with precision. This method is particularly effective for materials that are difficult to cut using traditional methods, such as metals, glass, and composites. The versatility of waterjet cutting makes it an attractive option for a wide range of industries, including automotive, aerospace, and architecture. With its ability to handle intricate designs and complex geometries, waterjet cutting has become a go-to solution for manufacturers looking to innovate and push the boundaries of design.

How Waterjet Cutting Works

The process begins with a pump that generates water at extremely high pressures, typically ranging from 30,000 to 90,000 psi. This pressurized water is then directed through a small nozzle, creating a focused jet that can slice through materials with ease. When abrasive materials are added, the cutting capabilities increase, allowing for the effective processing of tougher substances. The combination of water and abrasives, such as garnet, enhances the cutting action, making it possible to achieve intricate patterns and detailed cuts that would be challenging with conventional cutting methods.

Waterjet cutting is not only efficient but also eco-friendly. Since it uses water as the primary cutting medium, it produces minimal waste and does not generate harmful fumes or emissions, making it a sustainable choice for manufacturers. Additionally, the process can often be performed without the need for additional chemicals or solvents, further reducing its environmental impact. This eco-conscious approach is increasingly important in today’s manufacturing landscape, where companies are striving to adopt greener practices. For businesses seeking precision and sustainability, RHQ Store offers custom waterjet services tailored to meet diverse industrial needs.

Advantages of Waterjet Cutting

There are several advantages to using waterjet cutting services, which contribute to cost savings. Firstly, the precision of waterjet cutting minimizes material waste. Traditional cutting methods often result in excess scrap, but with waterjet technology, the cuts are clean and accurate, allowing for optimal use of materials. This efficiency not only reduces costs but also supports sustainable practices by maximizing the yield from raw materials.

Secondly, waterjet cutting is a cold cutting process, meaning that it does not produce heat-affected zones (HAZ). This characteristic prevents warping or altering the properties of the material being cut, reducing the need for additional finishing processes and further saving costs. Furthermore, the ability to cut a wide variety of materials, including soft materials like rubber and foam, as well as hard materials like titanium and ceramics, makes waterjet cutting an indispensable tool across diverse applications. From creating intricate signage to fabricating components for high-performance machinery, the adaptability of waterjet technology continues to expand its reach in the manufacturing sector.

Cost-Saving Benefits of Waterjet Cutting Services

Investing in waterjet cutting services can lead to substantial cost savings for businesses. These savings can be categorized into several key areas, including labor costs, material costs, and operational efficiency.

Reduced Labor Costs

One of the most significant benefits of waterjet cutting is the reduction in labor costs. The automation of the cutting process allows for faster production times, meaning fewer man-hours are required to complete projects. Additionally, the precision of waterjet cutting reduces the need for skilled labor to perform secondary operations, such as grinding or finishing.

By streamlining the production process, businesses can allocate their workforce more efficiently, focusing on other critical areas of operation. This not only saves money but also enhances overall productivity. Furthermore, the reduced reliance on manual labor can lead to fewer workplace injuries, thereby lowering insurance costs and improving employee morale. With a safer work environment and a more engaged workforce, companies can foster a culture of innovation and efficiency.

Minimized Material Waste

As mentioned earlier, the precision of waterjet cutting leads to minimized material waste. This is particularly important in industries where raw materials are expensive, such as aerospace and automotive manufacturing. By maximizing the use of materials, companies can significantly reduce their overall material costs.

Moreover, the ability to cut intricate designs and shapes with waterjet technology means that businesses can create parts that fit together perfectly, further reducing the likelihood of waste during assembly. This precision not only conserves resources but also contributes to a more sustainable manufacturing process, which is becoming increasingly important in today’s environmentally conscious market. Companies that prioritize sustainability can enhance their brand image and appeal to a growing base of eco-aware consumers, potentially leading to increased sales and customer loyalty.

Operational Efficiency

Waterjet cutting services can enhance operational efficiency in several ways. The speed of the cutting process allows for quicker turnaround times, enabling businesses to meet tight deadlines and respond rapidly to customer demands. This agility can be a competitive advantage in fast-paced markets.

Additionally, the versatility of waterjet cutting means that it can be used for a wide range of applications, from prototyping to large-scale production. This flexibility allows businesses to adapt to changing market needs without the need for significant investments in new equipment or technologies. The ability to switch between materials, such as metals, plastics, and ceramics, further enhances this adaptability, allowing companies to diversify their offerings and explore new markets without the burden of heavy capital expenditure. This adaptability not only keeps businesses relevant but also positions them to capitalize on emerging trends and technologies in their respective industries.

Choosing the Right Waterjet Cutting Service

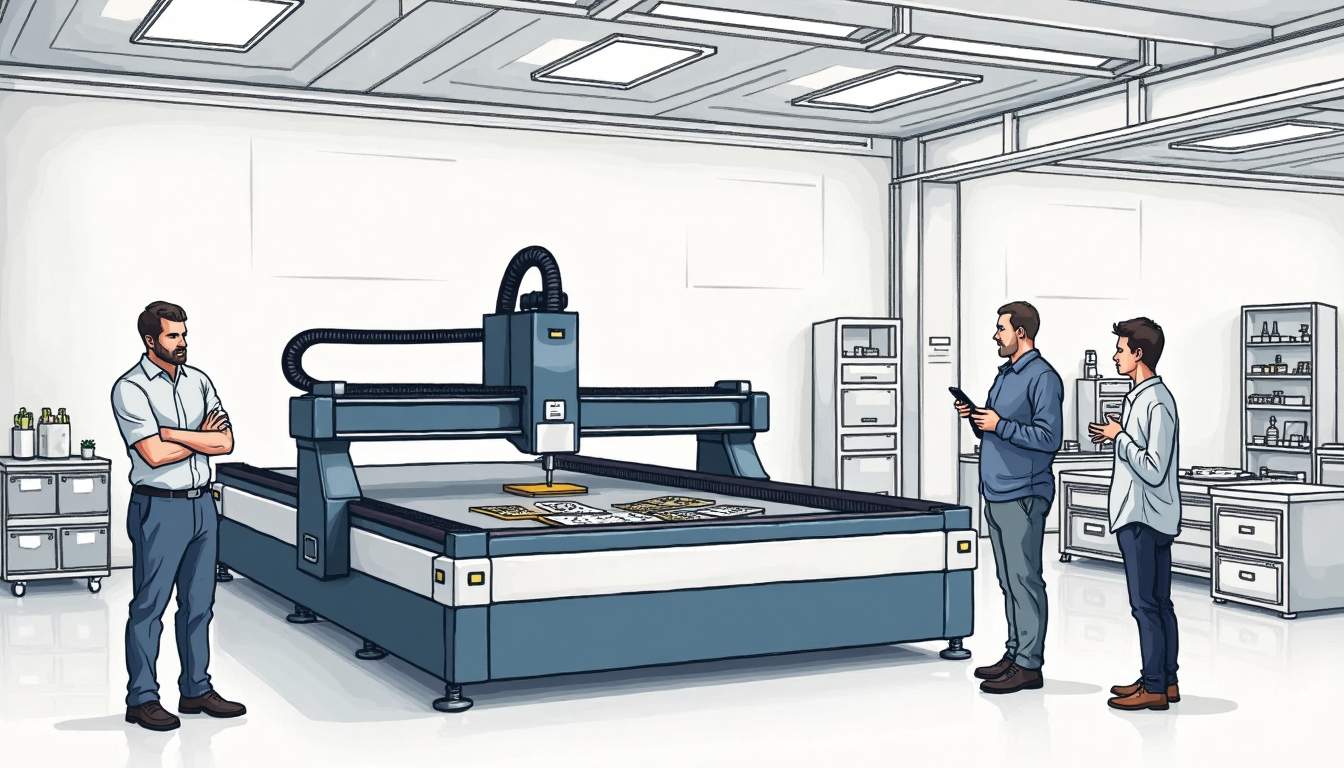

To fully realize the cost-saving benefits of waterjet cutting, it is essential to choose the right service provider. Not all waterjet cutting services are created equal, and selecting a partner that aligns with your specific needs can make a significant difference in both quality and cost.

Assessing Capabilities

When evaluating potential waterjet cutting service providers, it is crucial to assess their capabilities. Look for companies that have experience in your industry and can handle the specific materials you require. Additionally, inquire about their equipment and technology to ensure they are using the latest advancements in waterjet cutting.

Some providers may also offer additional services, such as design assistance or finishing processes, which can further streamline your production and reduce costs. A comprehensive service provider can be a valuable partner in achieving your manufacturing goals.

Evaluating Cost Structures

Understanding the cost structures of different waterjet cutting services is essential for making an informed decision. Some companies may charge based on material type, thickness, or complexity of the cut, while others may offer flat-rate pricing. It is important to obtain detailed quotes and compare them to ensure you are getting the best value for your investment.

Additionally, consider the long-term costs associated with each provider. While a lower upfront cost may be appealing, it is essential to factor in potential savings from reduced material waste and labor costs over time.

Customer Support and Communication

Effective communication and customer support are vital when working with a waterjet cutting service. A reliable provider should be responsive to inquiries and willing to collaborate closely with your team throughout the project. This partnership can lead to better outcomes and help address any potential issues that may arise during the cutting process.

Furthermore, a strong customer support system can assist in troubleshooting and resolving problems quickly, minimizing downtime and ensuring that production schedules are met.

Maximizing Efficiency in Waterjet Cutting

Once a waterjet cutting service has been selected, there are several strategies that businesses can implement to maximize efficiency and further enhance cost savings. These strategies focus on optimizing the cutting process, improving workflow, and leveraging technology.

Optimizing Cutting Parameters

To achieve the best results with waterjet cutting, it is essential to optimize the cutting parameters. This includes adjusting the pressure, speed, and abrasive flow rate based on the material being cut and the desired outcome. Working closely with the waterjet service provider can help identify the optimal settings for specific projects.

By fine-tuning these parameters, businesses can improve cutting speed, enhance precision, and reduce wear on the equipment, leading to lower operational costs and extended machine life.

Implementing Efficient Workflow Practices

Efficient workflow practices can significantly impact the overall productivity of waterjet cutting operations. This includes organizing the workspace, scheduling jobs effectively, and ensuring that all necessary materials and tools are readily available. A well-organized workflow minimizes delays and helps maintain a steady production pace.

Additionally, training employees on best practices for operating waterjet cutting machines can further enhance efficiency. Skilled operators are better equipped to troubleshoot issues and maintain optimal performance, ultimately leading to cost savings.

Leveraging Technology and Software

Incorporating technology and software solutions can also improve the efficiency of waterjet cutting operations. Advanced software can assist in designing parts, optimizing cutting paths, and managing production schedules. By utilizing these tools, businesses can streamline their processes and reduce the likelihood of errors.

Moreover, some waterjet cutting services offer online platforms for order management and tracking, allowing businesses to monitor their projects in real-time. This transparency can enhance communication and ensure that production stays on track.

Conclusion

Efficient waterjet cutting services provide a valuable opportunity for businesses to save costs while maintaining high-quality production standards. By understanding the technology, recognizing the cost-saving benefits, and choosing the right service provider, companies can leverage this advanced cutting method to enhance their operations.