Efficient material handling is a crucial factor in ensuring seamless industrial operations. Whether in mining, construction, metallurgy, or recycling industries, the need for reliable and consistent feeding systems cannot be overstated. A reciprocating feeder is an essential piece of equipment designed to optimize the transportation of bulk materials, reduce operational downtime, and enhance productivity.

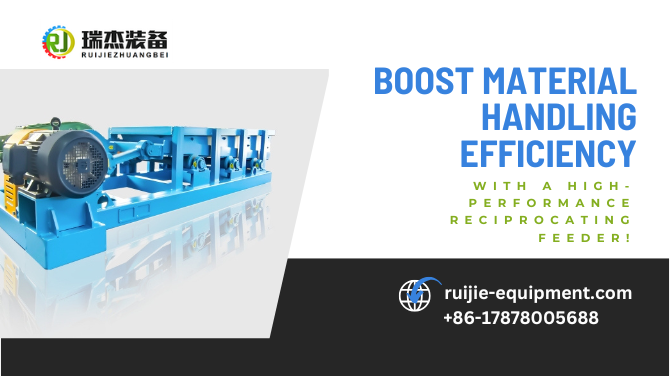

At Guangxi Ruijie Slag Equipment Manufacturing Co., Ltd., we specialize in manufacturing high-performance reciprocating feeders that are engineered to meet the demanding needs of modern industries. These feeders offer precision-controlled feeding, ensuring a steady and uniform material flow to downstream processing equipment.

What is a Reciprocating Feeder?

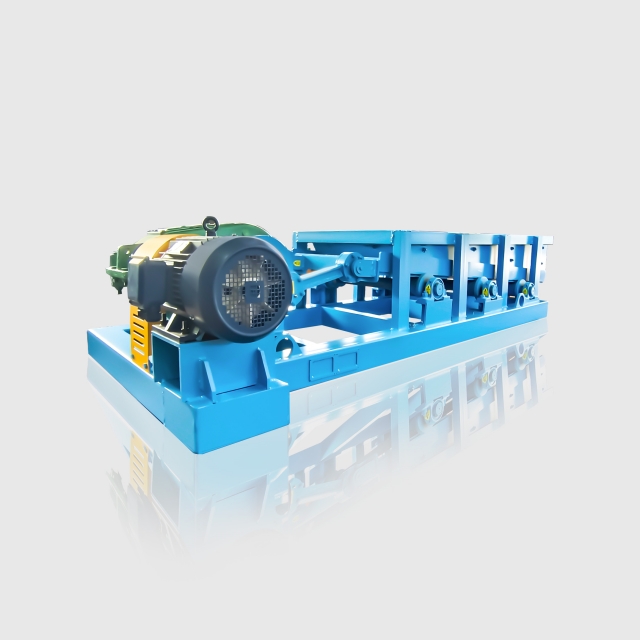

A reciprocating feeder is a mechanical device used to transport bulk materials in a controlled and uniform manner. It operates through a back-and-forth (reciprocating) motion that gradually pushes material from a hopper or storage bin onto a conveyor belt, crusher, or other processing equipment.

Unlike traditional feeders, which rely on gravity or vibrations alone, reciprocating feeders ensure a steady flow rate, reducing blockages and minimizing material spillage. This makes them ideal for handling a wide range of materials, including coal, ores, aggregates, slag, and other heavy or abrasive substances.

How Does a Reciprocating Feeder Work?

The working mechanism of a reciprocating feeder involves a series of coordinated movements:

- Material Loading: The feeder receives bulk materials from a hopper, silo, or bin.

- Reciprocating Motion: A hydraulically or mechanically driven tray moves back and forth, gradually pushing materials forward.

- Controlled Discharge: The movement ensures an even and controlled discharge onto the next stage of processing, such as a conveyor belt or crusher.

- Return Stroke: The feeder tray moves back to its original position to repeat the cycle, ensuring a continuous material flow.

This process minimizes material surges, prevents clogging, and enhances efficiency by ensuring a smooth and uninterrupted feeding operation.

Why Are Reciprocating Feeders Essential for Material Handling?

1. Improved Efficiency and Productivity

By providing a steady and controlled material flow, a reciprocating feeder prevents equipment overload, reduces bottlenecks, and enhances overall processing speed. As a result, there is less downtime and more production.

2. Versatile Application Across Industries

Whether in mining, construction, metallurgy, or cement plants, reciprocating feeders are widely used to transport various materials efficiently. Their adaptability makes them a vital asset in multiple industrial settings.

3. Enhanced Equipment Longevity

Uneven material feeding can cause excessive wear and tear on processing equipment. A reciprocating feeder ensures an even distribution of materials, reducing stress on crushers, screens, and conveyor belts, thereby extending their lifespan.

4. Reduced Material Spillage and Waste

Uncontrolled material flow can lead to spillage and waste, increasing operational costs. With a reciprocating feeder, material discharge is precise and controlled, minimizing losses and improving resource utilization.

5. Lower Energy Consumption

Compared to other feeding systems, reciprocating feeders operate with minimal power consumption while delivering maximum efficiency. Their mechanical simplicity translates to lower energy usage and reduced operational costs.

Key Features of a High-Performance Reciprocating Feeder

When selecting a reciprocating feeder, it is important to look for key features that enhance efficiency and durability. Some of these include:

- Robust Construction – Built with heavy-duty materials to withstand harsh working conditions.

- Adjustable Feed Rate – Allows customization based on material type and processing requirements.

- Low Maintenance Design – Fewer moving parts mean lower maintenance costs and reduced downtime.

- Smooth and Silent Operation – Minimizes noise pollution while ensuring a seamless feeding process.

- High Load Capacity – Designed to handle large volumes of material efficiently.

At Guangxi Ruijie Slag Equipment Manufacturing Co., Ltd., we manufacture reciprocating feeders that integrate these advanced features, ensuring optimal performance for industrial applications.

Industries That Benefit from Reciprocating Feeders

The reciprocating feeder is a versatile piece of equipment that plays a vital role in various industries, including:

- Mining and Quarrying – Facilitates the efficient movement of ores, rocks, and aggregates.

- Metallurgy – Used to feed raw materials into smelting furnaces and processing units.

- Cement and Construction – Ensures steady feeding of cement raw materials such as limestone and gypsum.

- Power Plants – Plays a critical role in handling coal and biomass materials for energy production.

- Recycling Facilities – Used to transport slag, scrap metal, and other recyclable materials.

No matter the industry, a reciprocating feeder enhances material handling operations, boosting efficiency and reducing operational costs.

How to Choose the Right Reciprocating Feeder

Selecting the right reciprocating feeder for your business requires careful consideration of several factors:

- Material Type & Characteristics – Consider the size, weight, and abrasiveness of the materials being handled.

- Feeding Capacity – Ensure the feeder can handle the required material volume per hour.

- Operational Environment – Choose a feeder designed for the specific working conditions (e.g., high temperatures, corrosive materials).

- Automation & Control Features – Opt for feeders with adjustable feed rates and automation capabilities for greater efficiency.

- Manufacturer Support & Reliability – Work with a reputable manufacturer like Guangxi Ruijie Slag Equipment Manufacturing Co., Ltd. to ensure quality, reliability, and after-sales support.

A reciprocating feeder is an indispensable tool in industrial material handling, offering unparalleled efficiency, precision, and reliability. From mining and metallurgy to construction and recycling, these machines optimize operations by ensuring controlled material flow, reducing equipment wear, and enhancing overall productivity.

At Guangxi Ruijie Slag Equipment Manufacturing Co., Ltd., we design and manufacture high-performance reciprocating feeders tailored to meet the unique demands of various industries. Our feeders are built for durability, efficiency, and ease of maintenance, making them a valuable investment for any material handling operation.

If you’re looking to boost productivity, reduce downtime, and improve material handling efficiency, contact us today to learn more about our reciprocating feeders!

FAQs

- 1. What materials can a reciprocating feeder handle?

A reciprocating feeder is suitable for a wide range of bulk materials, including coal, ore, aggregates, slag, and construction materials.

- 2. How does a reciprocating feeder differ from a vibrating feeder?

While vibrating feeders use rapid vibrations to move materials, reciprocating feeders use a back-and-forth motion for controlled feeding. Reciprocating feeders are ideal for handling heavy, abrasive materials.

- 3. Is a reciprocating feeder energy-efficient?

Yes! Reciprocating feeders operate with minimal energy consumption while maintaining high efficiency, making them a cost-effective choice for industries.

- 4. How do I maintain a reciprocating feeder?

Routine maintenance involves inspecting wear components, lubricating moving parts, and ensuring proper alignment. Regular maintenance helps extend the lifespan of the machine.

- 5. Where can I buy a high-quality reciprocating feeder?

For durable and efficient reciprocating feeders, contact Guangxi Ruijie Slag Equipment Manufacturing Co., Ltd.. We provide top-tier equipment designed to optimize material handling operations.