A fiber laser cutting machine uses a highly focused beam of light, generated by stimulating a special fiber optic cable, to slice through metals with extreme precision and speed. Unlike traditional cutting tools that physically contact the material, fiber lasers rely on the energy of photons concentrated in a minuscule spot. This energy heats and melts or vaporizes the metal at the focal point, allowing intricate shapes and clean cuts without applying pressure or mechanical force.

The precision, efficiency, and adaptability of fiber laser cutting machines have revolutionized manufacturing, fabrication, and many industrial sectors worldwide. Let’s explore how this technology works, its applications, and why it continues to be the preferred choice for modern cutting needs.

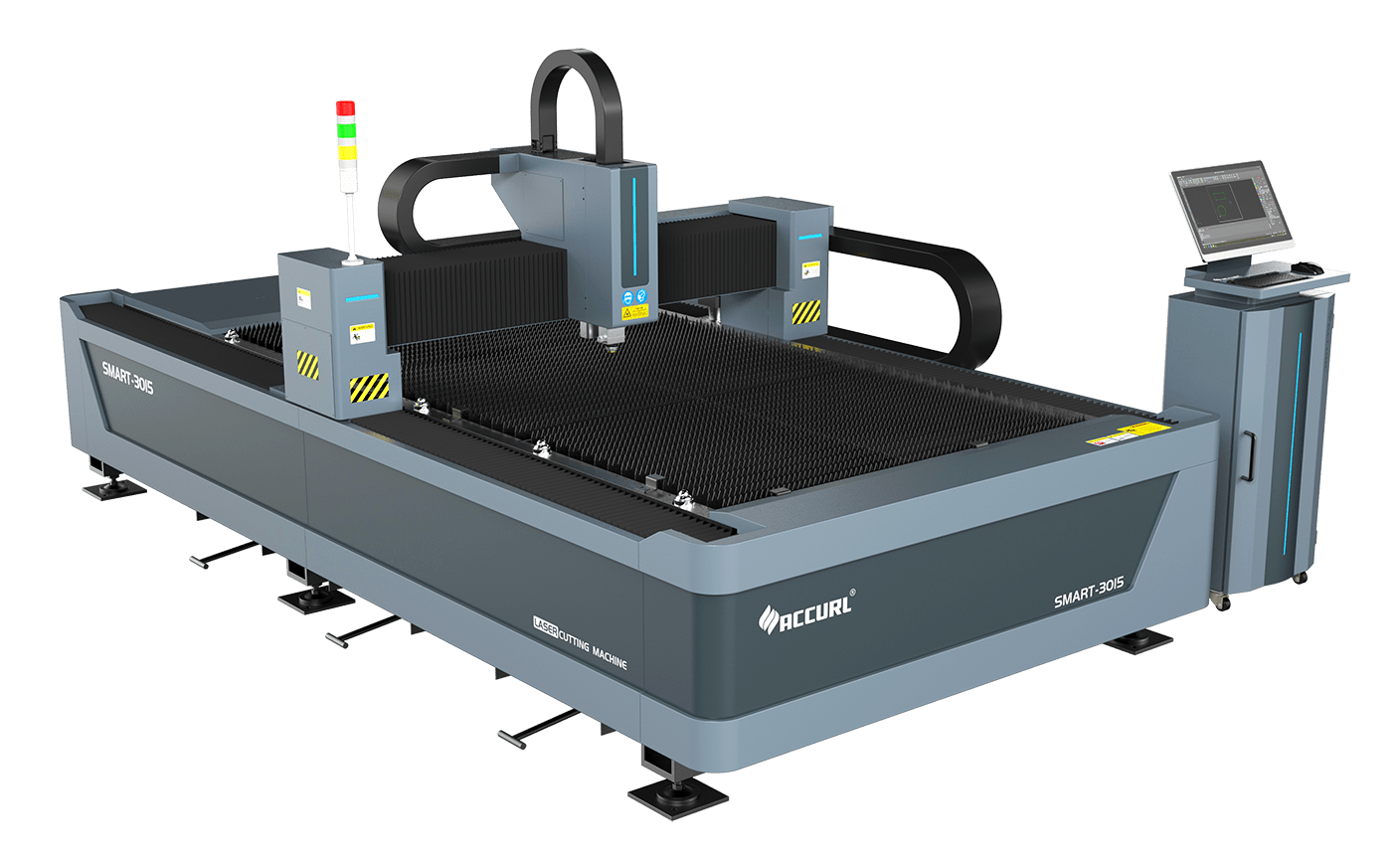

Understanding Fiber Laser Cutting Machines

At the heart of a fiber laser cutting machine lies the fiber laser source. It emits a laser beam through optical fibers doped with rare-earth elements such as ytterbium. This beam is then delivered to the cutting head via fiber optics, enabling flexibility and stability during operation.

When this intense beam is focused onto a metal surface, the high energy density rapidly raises the temperature, causing the metal to melt, burn, or vaporize. A high-pressure gas, often nitrogen or oxygen, blows away the molten material, creating a clean cut along the desired path. This non-contact process ensures minimal thermal distortion and prevents physical wear on cutting tools.

Versatility in Materials and Thickness

One of the reasons fiber laser cutting machines are highly sought after is their ability to handle a wide range of metals. Stainless steel, carbon steel, aluminum, brass, copper, and titanium can all be precisely cut with varying thicknesses—from very thin sheets to thick plates.

The machine’s settings can be adjusted to match the material type and thickness, enabling operators to achieve consistent, accurate results whether creating delicate patterns or heavy-duty industrial components.

Precision and Speed Combined

Fiber laser cutting machines offer an unparalleled combination of speed and precision. The laser beam can be finely controlled to follow intricate designs, making it ideal for industries that require detailed metalwork like automotive, aerospace, electronics, and signage.

The high speed is not only due to the laser’s rapid movement but also because there’s no need for physical cutting tools to slow down for wear or changing materials. The laser operates continuously, reducing downtime and increasing throughput.

Automation and Integration Capabilities

Modern fiber laser cutting machines come equipped with advanced software and automation features. Computer Numerical Control (CNC) systems guide the laser path based on digital design files, minimizing human error and maximizing repeatability.

Some machines also integrate with other manufacturing processes such as robotic arms or conveyor systems to streamline production lines. This automation capability reduces labor costs and accelerates project timelines, benefiting manufacturers who prioritize efficiency.

Environmental Considerations

Fiber laser cutting machines are often considered more environmentally friendly than some conventional cutting methods. Since the process is contactless, it produces less waste and fewer pollutants. The energy consumption is also optimized, as fiber lasers typically require less power compared to CO2 lasers or plasma cutters for similar tasks.

Additionally, the precise cuts mean less material scrap, further contributing to resource efficiency.

Choosing the Right Fiber Laser Cutting Machine

Selecting the ideal fiber laser cutting machine depends on specific operational requirements. Factors include the types of metals to be cut, maximum thickness, desired speed, precision needs, and budget.

Leading manufacturers offer a range of models with various power outputs, cutting areas, and control systems. Some machines are tailored for small-scale workshops, while others are designed for heavy industrial applications with large sheets and high production volumes.

Maintenance and Longevity

Fiber laser cutting machines are known for their durability and low maintenance compared to older laser types. The solid-state fiber laser source has no moving parts inside, reducing wear and the need for frequent servicing.

Operators should regularly inspect the optics, gas supply, and machine calibration to ensure consistent cutting quality. Proper maintenance extends the machine’s lifespan and sustains high productivity over time.

Industry Applications

Across numerous sectors, fiber laser cutting machines have become indispensable tools. In automotive manufacturing, they facilitate the creation of precise body panels and components. Aerospace companies use them for complex parts requiring tight tolerances. Electronics manufacturers benefit from their ability to cut thin metals for circuit boards and casings.

Even artistic and architectural industries have embraced fiber laser cutting for decorative metalwork and customized designs. The technology’s flexibility to produce both functional and aesthetic products adds to its widespread appeal.

Cost and ROI Considerations

While fiber laser cutting machines require a significant initial investment, their operational efficiency and quality often translate into cost savings over time. Faster processing, reduced waste, minimal tool replacement, and lower maintenance contribute to an attractive return on investment.

Businesses aiming to improve production capacity and quality standards frequently find that fiber laser cutting machines justify their costs through increased output and enhanced product quality.

Final Thoughts

The fiber laser cutting machine represents a leap forward in metal cutting technology, combining precision, speed, and versatility in a single package. By utilizing the power of focused light rather than mechanical tools, it achieves results unattainable with traditional methods.

Whether for intricate designs or heavy industrial applications, this technology offers unmatched consistency and efficiency. For manufacturers seeking to stay competitive and innovative, investing in a fiber laser cutting machine is a strategic move that unlocks new possibilities in metal fabrication.

If you want your business to harness cutting-edge metal processing, explore the range of fiber laser cutting machines available today—designed to meet diverse needs and propel your production capabilities to the next level.